How Prefinished Plywood Is Changing the Game in Modern Woodworking

At the end of the day, in the world of woodworking, cabinetry, and home renovation, one type of plywood stands out: prefinished plywood. While unsanded plywood typically needs to be sanded, stained, and sealed, prefinished plywood is ready to install. Being easy to build and having a long-lasting surface, a construction board that saves time, naturally becomes the best choice for the portfolio of builders, contractors, furniture makers, and even home improvers.

This guide discusses the characteristics, advantages, uses, and considerations for prefinished plywood to help you determine if pre-finished plywood is the best fit for your project.

What Is Prefinished Plywood?

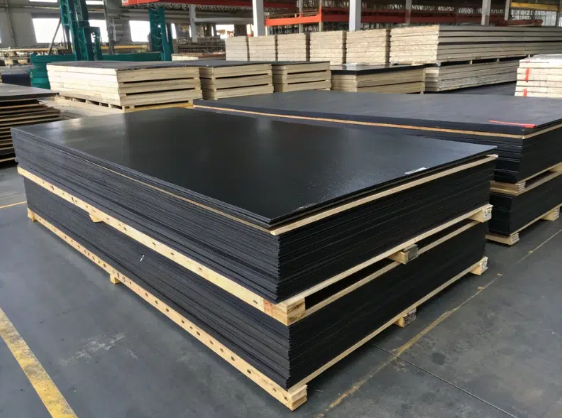

As a factory-finished product, there is no on-site drying or other difficult on-site treatment, such as sanding, and downtime is minimized with prefinished plywood. There’s no need to begin with all the time-consuming labor of preparing raw plywood — these panels arrive with a clear or stained finish already applied. The coating may be one of UV-cured varnish, polyurethane, or other protective layers aiming to improve the longevity, aesthetics,, s and scratch or moisture resistance of the flooring.

This makes prefinished plywood perfect for anyone who prioritizes efficiency and uniformity. It also gets rid of a lot of the finishing steps that take so much time, so you can concentrate more on building and less on prepping.

Key Advantages of Prefinished Plywood

Time-Saving

There are a variety of advantages to using prefinished plywood, but it saves more time than anything else. Because the panels are already sanded and finished, you can cut, assemble, and install them immediately without the need for finish work.

Professional Finish

The finish applied in the factory is usually more uniform and tougher than anything people can apply at home. This will guarantee you get a neat and professional finish with minimum imperfections.

Durability

A number of prefinished plywood panels feature UV-cured finishes that can withstand fading, scratching, and wear and tear. This means they are ideal for high-traffic areas, like kitchens, an office, or shelving.

Eco-Friendly Options

Some brands also make sustainable options with low-VOC coatings and/or sustainably harvested wood for their prefinished plywoods. It can also be a more environmentally-friendly option for individuals wanting to reduce their environmental footprint.

Cost-Effective in the Long Run

This prefinished plywood costs more upfront than raw plywood, but you’ll save on finishing materials, labor, a nd time. The savings can add up for major projects.

Common Applications of Prefinished Plywood

We carry prefinished plywood for several different uses:

Cabinets – Perfect for kitchen cabinets, bathroom vanities, and storage units for their clean and durable finish.

Shelving- Beautiful finish and scratch resistant also an ideal shelf option for many home theaters or closet systems.

Furniture Making – Whether you’re creating tables or dressers, pre-finished plywood enables furniture makers to produce a more uniform product in less time.

Walls and Interior Applications – It offers a sleek and modern look for wall panels, office spaces, and commercial interiors.

DIY Projects- Do It Yourself hobbyists can enjoy the convenience of using this mold making and have no waiting time, just DIY all manner of home jewelry or ornaments faster and easier.

What to Think About Before You Purchase Prefinished Plywood

There are several things to consider when using prefinished plywood.?

Cost – You can expect to spend more on the front end than with unfinished plywood. But usually this cost gets offset because labor and finishing materials are saved.

Little Personalization – As the panels are already painted, you have a limited choice of stains or paints. Unfinished plywood might be better if you want a particular color or texture.

Cutting and Edge Finishing- If you cut prefinished plywood, the exposed edges will not have a cut finish on them. This is to say, you might want edge banding or another surface treatment for a totally seamless appearance.

Availability – Prefinished isn’t as widely available in many smaller local stores. You might have to obtain from special suppliers.

Prefinished vs. Unfinished Plywood

Prefinished vs. Unfinished Plywood: Whether you’re selecting prefinished vs. unfinished plywood depends on your project. If you need some design flexibility, unfinished plywood might be most suitable. But if you need your material to be fast, consistent, and strong, prefinished plywood is absolutely the way to go.

For contractors with many projects on their hands, prefinished plywood can save weeks of labor. For DIY furniture-making homeowners, it takes the headache out of applying layer after layer of finish.

Table of Contents

Final Verdict

Prefinished plywood: An architectural game-changer.Pre-finished products in plywood Sheets and boards offer ready-to-use. Yes, it is ready-to-use, durable, and can be made elegant! IT saves time, decreases the cost of labor, and provides a professional finish to your work right out of the box. It is more expensive and doesn’t allow a lot of customisation, but for most uses the advantages outweigh the disadvantages.

Prefinished plywood is a great investment if you want it fast without compromising quality. Whether you are constructing cabinets, furniture, or wall panelling, distilled down to a simple approach to effective construction that combines ease of use with strong joints.